So I decided that I'd experiment a bit with printing surfaces.

I've got my glass printing surface, and that's working great, but I'd still stretching Kapton over the top of it.

The Kapton tapes job is to provide a texture for the ABS plastic to stick to as it's extruded.

There have been many reports that people are not using Kapton, (which tends to get damaged over time) and are instead getting their textured surface from a film of hair spray that can be easily applied and easily cleaned off of the print bed.

Given that the point of both the Kapton and the hairspray is to provide texture I wondered if using a piece of frosted glass would allow me to have a durable print surface that I wouldn't need to keep applying, and that wouldn't wear out.

I used some glass etching cream, and painted it liberally over the surface of the glass, and left it for 15 minutes, the glass plate was then washed.

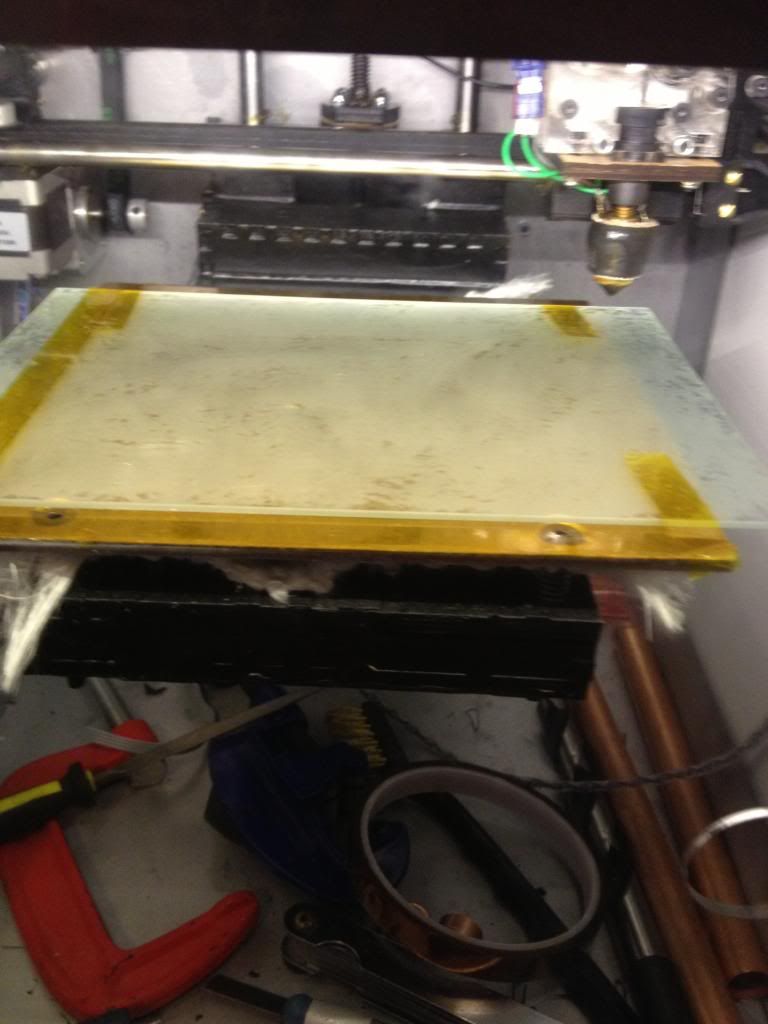

I secured the glass plate to the print bed with 6mm Kapton tape looped around the bed, and turned the bed on.

I realise that the glass is going to be at a cooler temperature than the aluminium bed that it sits on, so the print bed won't be the same temperature that the aluminium bed normally gets to.

To compensate for this I turned the temperature up in the pronterface print software and measured the glass surface temperature using a thermo couple.

When the glass was at temperature I attempted to print on it.

I found that the ABS did not stick at all.

despite what the common understanding or rumour says, it appears that Kapton tape provides a bit more than texture for the plastic to stick to.

No comments:

Post a Comment