Well, I've finally done it.

Of course to understand why the word finally is applicable you have to understand my back story.

There is a modern day "maker" movement, a huge open source project, called RepRap.

RepRap is the foundation that takes care of the project, the project is to build (as much as is practically possible) machines that can build themselves.

it's not really a new thing as much, you've been able to cut gears to make lathes on lathes for a long time, and been able to mill flat tables for use on milling machines for a long time too.

Reprap machines are computer controlled 3d printers.

The way that they work is you feed them a length of plastic string, the machine melts the string in a hot chamber, and then pushes the melted plastic through a nozzle onto a build platform.

then the build platform, or nozzle move ever sl slightly away from each other.

and another layer is squished out of the machine, slowly but surely building up a 3d object layer by layer.

I first heard about the project in a staff news letter whilst I was working at the university of Bath in the UK, (that's where this open source project started. Fused filament 3d printing had been around a long time before that, but I had never heard of it!)

and ever since hearing about it, I've always wanted on.

but there was always been one problem. price.

It seems that there are two ways to get a 3d printer.

buy the plastic parts you need from someone who has already printed them, buy the electronics board, but stepper motors, smooth rods, threaded rods, belts sprockets, pulleys wire, power supplies, bearings bolts, etc, etc, etc...

which in total seemed to cost around £500 - £1000 to source. and about ten weeks for a first timer to build and trouble shoot. (that's after you decided which of the many many designs you wanted to make!

The second option was to buy, where buying costs £1000 and upwards.

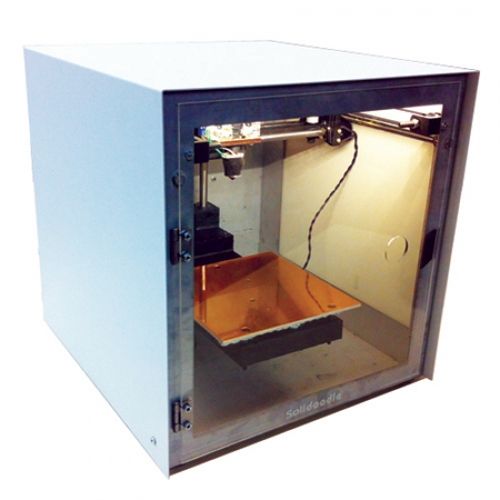

That was until a small start up company called solidoodle came along. they are offering their Solidoodle 2 printer, a complete ready to go package.

For five hundred dollars,

yes, dollars.

the machine is a steel framed box, with an aluminium build platform measuring 150m x 150mm, the platform moves up and down by 150mm also, (this means that I can print anything up to this size (in one piece) or anything in the world, if I'm willing to glue bits together after printing.

The frame is supposed to be strong enough that you could stand on it.

A cover for the open frame, and a heated bed (rather than acrylic bed) are $100 add-ons.

when you add a roll of filament to the order and international shipping. the complete price for a working 3d printer, that should work straight from the box is $750 US dollars.

Or around £500 sterling.

I've ordered, delivery time is 8 - 10 weeks I can hardly wait.

No comments:

Post a Comment